Introduction

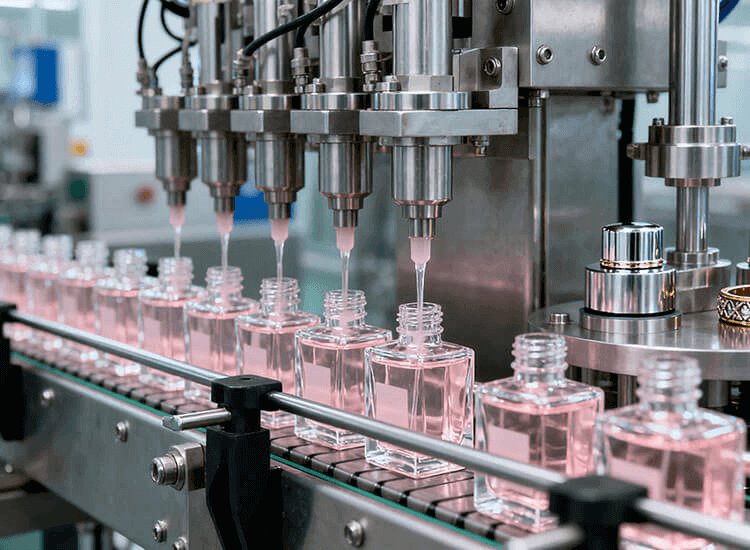

Custom car air freshener manufacturing plays a critical role in the success of private label car air freshener brands and wholesale distributors worldwide. While car air fresheners may appear to be simple consumer products, the reality behind consistent quality, scent performance, compliance, and scalability is far more complex.

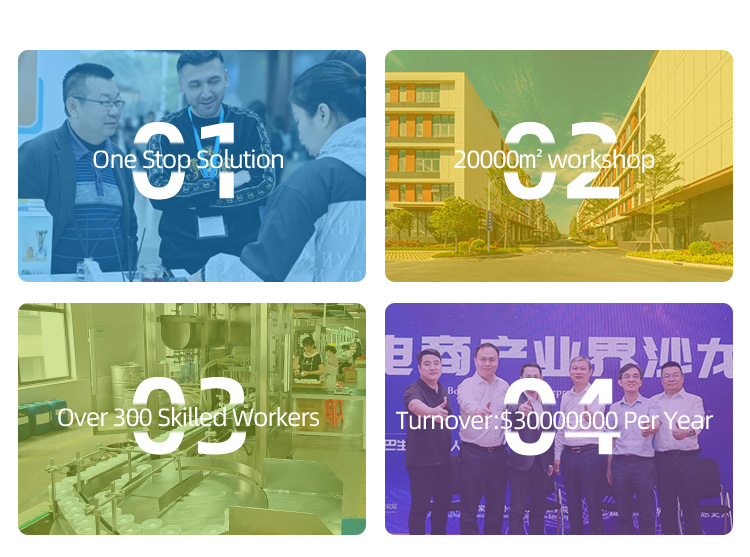

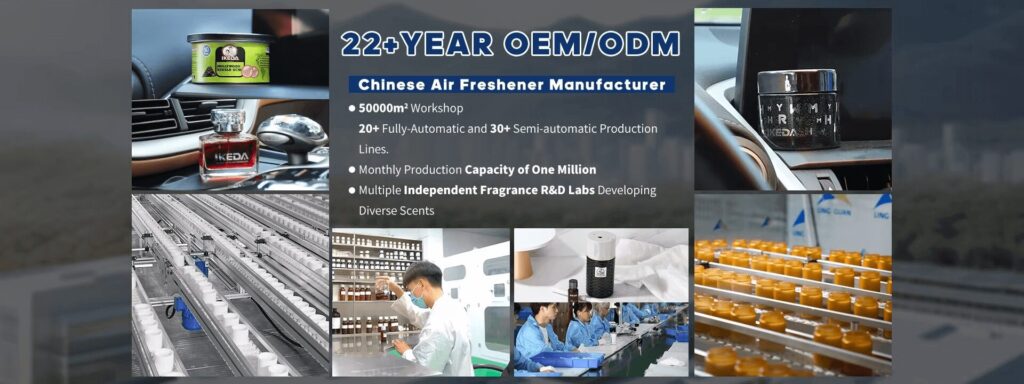

As a China-based car air freshener manufacturer with extensive OEM and ODM production experience, we have supported brands, importers, and resellers across Europe, North America, Southeast Asia, and the Middle East. Over the years, we’ve seen what works—and what often causes costly delays or product failures.

This guide is written from a manufacturer’s perspective to help brands and resellers understand the real factors behind successful custom car air freshener projects, from MOQ decisions to fragrance development and long-term supply reliability.

Understanding Custom Manufacturing vs. Off-the-Shelf Products

Many buyers begin with stock designs, which can be useful for market testing. However, custom manufacturing allows brands to:

- Control scent identity and longevity

- Differentiate packaging and visual branding

- Adjust formulations for regional preferences

- Build long-term product consistency

In competitive markets, off-the-shelf products often struggle to maintain margins. Custom solutions, when executed correctly, create defensible brand value.

MOQ: What Is Realistic for Custom Car Air Fresheners?

Minimum order quantity (MOQ) is one of the most misunderstood aspects of custom car air freshener MOQ planning.

Typical MOQs by customization level:

- Stock items with private label packaging: 1,000–2,000 units

- Custom fragrance with standard molds: 3,000–5,000 units

- Full OEM/ODM (custom scent + packaging + format): 5,000–10,000 units

From a manufacturing standpoint, MOQ is not arbitrary—it reflects raw material sourcing, fragrance batching, packaging setup, and quality control requirements.

Well-planned MOQs help maintain stable scent profiles and reduce batch-to-batch variation.

Private Label & OEM Options Explained

Private label manufacturing typically involves:

- Existing product formats

- Pre-tested fragrance bases

- Brand-specific packaging and labeling

OEM/ODM projects go further and may include:

- Custom fragrance formulation

- New mold development

- Market-specific compliance adjustments

- Retail-ready packaging engineering

For brands seeking long-term growth, OEM/ODM car air freshener solutions provides significantly stronger differentiation.

Scent Development: More Than Just “Choosing a Fragrance”

Fragrance is the core of any air freshener—but it is also the most technically sensitive component.

Professional car air freshener fragrance development considers:

- Volatility and evaporation curves

- Heat resistance (especially for vehicle interiors)

- Regional scent preferences

- Shelf-life stability

In our experience, many brands underestimate how climate, packaging materials, and carrier bases affect real-world performance. This is why pre-production sampling and aging tests are essential before mass production.

Compliance & Market Regulations

For international distribution, compliance is not optional.

Most reputable manufacturers provide:

- MSDS (Material Safety Data Sheets)

- IFRA compliance documentation

- REACH compliance for EU markets

- Additional certifications upon request (SGS, ISO audits)

Early compliance checks prevent customs delays and protect brand reputation.

Quality Control from a Manufacturer’s Perspective

Quality control in car air freshener manufacturing extends beyond appearance.

Third-party inspections conducted by organizations such as SGS inspection services help ensure consistent quality.

Key checkpoints include:

- Raw material verification

- Fragrance batch consistency testing

- Leakage and evaporation testing

- Packaging durability inspection

- Pre-shipment quality audits

Brands that treat QC as a collaborative process with their manufacturer typically experience fewer post-market issues.

Lead Times, Logistics & Supply Planning

Typical production timelines:

- Sampling & approval: 7–14 days

- Mass production: 25–35 days

- Sea freight: 20–40 days (destination dependent)

Manufacturers often advise clients to plan orders 2–3 months ahead to maintain inventory continuity and avoid rush costs.

Eco-Friendly & Sustainable Manufacturing Options

Sustainability is becoming a purchasing factor, particularly in Europe.

Available options include:

- Biodegradable paper cards

- Reduced-VOC fragrance formulations

- FSC-certified or recycled packaging materials

Sustainable options can be integrated without sacrificing scent performance when planned early.

Choosing the Right Manufacturing Partner

Beyond pricing, reliable manufacturers offer:

- Transparent communication

- Stable formulation records

- Scalable production capacity

- Long-term product consistency

A manufacturing partnership should support growth, not create operational risk.

Conclusion

Custom car air freshener manufacturing is not simply about producing a product—it is about building a scalable, compliant, and differentiated brand offering.

By understanding MOQs, fragrance development, compliance standards, and quality control from a manufacturer’s perspective, brands and resellers can avoid common sourcing pitfalls and position themselves for long-term success.

If you are evaluating custom or private label car air freshener projects, working with an experienced manufacturer can help clarify realistic options and streamline decision-making. We welcome discussions focused on project feasibility, market fit, and sustainable production planning.

If you are planning a custom or private label car air freshener project, feel free to contact our team to review feasibility, MOQ options, and production timelines.